Ultra-lightweight (11Kg) Plastering Cobot

Patented System Method: Realizing Spraying & Leveling

One-Step Completion. Effortless Finish.

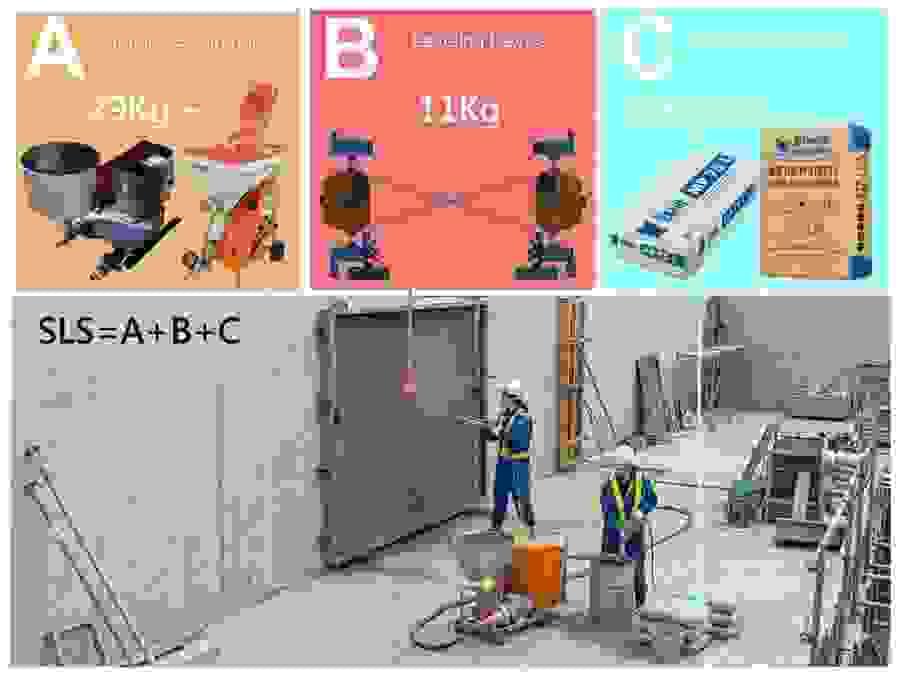

SLS ?

SLS (Speed Leveling System)

Led by a practicing architect, SLS was developed by a specialized R&D team combining years of architectural design and on-site construction experience. By leveraging existing equipment, materials, and workforce characteristics, we are dedicated to inventing new working methods to solve issues related to poor construction environments, quality inefficiencies, and the shortage of skilled labor.

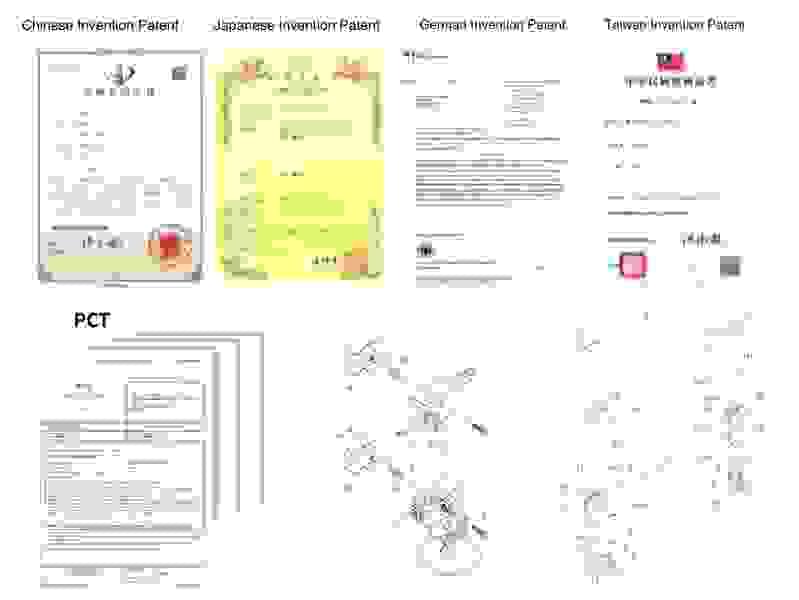

After years of testing and refinement, the team has secured invention patents in multiple countries and successfully developed the core technology: the "SLS Ultra-lightweight Plastering Collaborative Cobot" and its associated "Patented System Method."

The core device of the robot weighs only 11 kg, making it suitable for construction sites of all sizes, as well as indoor and outdoor walls. Compared to competing products on the market, its key advantages are its ultra-lightweight design, affordability, ease of operation, and a level of productivity and quality that rivals large-scale machinery.

SLS (Solve with Logic and Strategy)

The SLS R&D team systematically deconstructed the plastering process and used logical analysis to identify "leveling" as the critical bottleneck affecting efficiency and quality. Based on this insight, the team discarded the traditional mindset of "apply then press" and redefined the logic to a new strategic method: "Spray then Shave."

This shift in logical strategy allowed for significant simplification of the equipment, successfully achieving an ultra-lightweight design and high flexibility for both indoor and outdoor conditions. Once this core technology was perfected, it was integrated with existing pumping equipment and dry-mix materials to form the "SLS Patented System Method," a solution that combines high efficiency, high quality, and cost advantages.

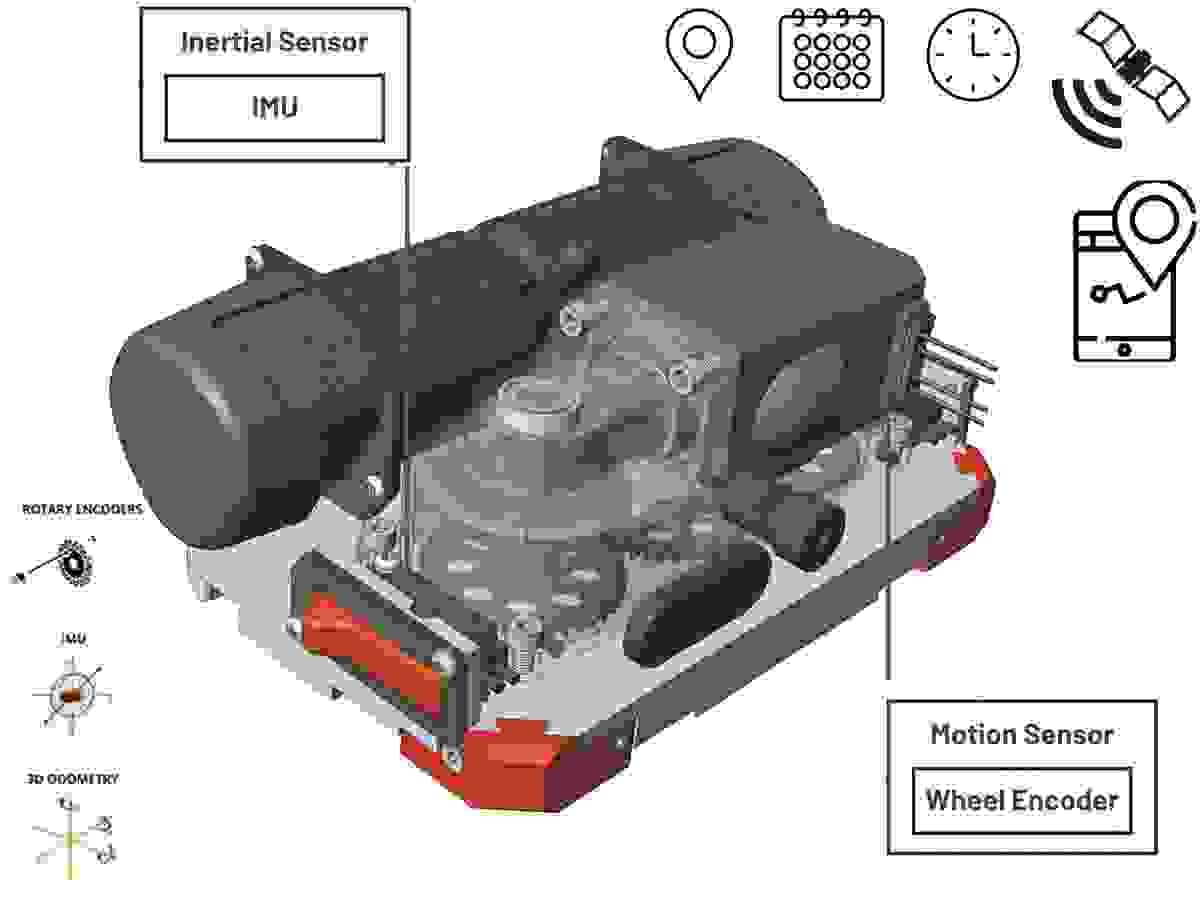

Core Device & Intelligence

SLS Patented Core Device The SLS core device is built on industrial-grade design principles, featuring a robust "Three-Electric System" (Battery, Motor, and Electric Control). This ensures the AGV (Automated Guided Vehicle) operates stably under long hours, high loads, and complex environments, meeting strict industrial standards.

In terms of intelligence, SLS utilizes a multi-sensor stack design, integrating GPS positioning and IMU (Inertial Measurement Unit) data collection. This significantly improves positioning accuracy and operational reliability while moving. Powered by AI algorithms, the system performs real-time environmental perception and status analysis, enabling autonomous decision-making and dynamic adjustments for true automation.

This core device not only ensures safe, smooth, and reliable movement within the site but also effectively supports the scheduling of manpower, machinery, and materials. Through site configuration and device tracking, managers can monitor real-time conditions, improving resource allocation efficiency and reducing manual operational risks.

Additionally, the SLS device supports remote mobile control and backend maintenance support, allowing management to monitor equipment status, adjust operations, and arrange maintenance in real-time, ensuring smooth human-machine collaboration and enhancing overall operational efficiency.

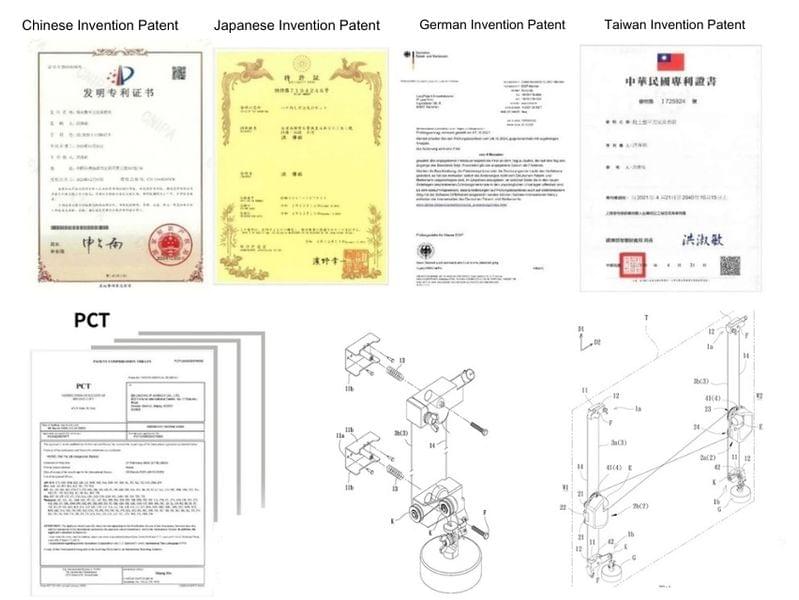

Patent Protection

SLS Core Technology & Patent Protection We have successfully developed unique ultra-lightweight and high-performance wall leveling technology and have obtained invention patents as illustrated.

Furthermore, we have filed for PCT (Patent Cooperation Treaty) international patent protection. This will help us secure patents in major global markets in the future, ensuring our technological leadership and exclusivity.

System Methodology

SLS System Method: From "Rule by Man" to "System Governance"

- Builds construction quality into the "methodology logic."

- Reduces structural reliance on highly skilled workers.

- Provides a stable, easy-to-train, and replicable construction model.

- Effectively lowers quality risks and management costs.

- Allows adopters to upgrade to automated methods quickly without discarding existing resources.

Suitable for construction environments facing labor shortages and rising quality demands. It is a solution integrating three major components:

A. Pumping Equipment

B. Leveling Device

C. Dry-mix Materials

The SLS System Method offers a scalable, manageable, replicable, and licensable wall plastering solution, transforming a highly labor-dependent process into an engineering system platform with high investment value.

Features

High Efficiency

Comprehensive efficiency of 20 ping/h (approx. 66 m²/h), which is over 5-7 times faster than traditional manual labor.

High Coverage

Comprehensive indoor/outdoor wall coverage of 80-90%. Single operation range: 1-6m wide, 1-4m high (depending on the environment).

High Quality

Precise positioning with controllable flatness, verticality, and thickness, ensuring consistent and excellent results.

Easy Operation

User-friendly human-machine interface; simple to understand. Enables one-key start for combined spraying and leveling operations.

Safety

Features collision protection, automatic obstacle stopping, and dynamic fault monitoring.

High Applicability

Suitable for spraying and leveling walls in various fields, including areas with openings (doors, windows) and parallelograms (e.g., stairwells).

Low Carbon Method

Compared to traditional methods, this system saves approximately 50-70% in thickness. Material saving equals carbon reduction.

WR Construction Machine Co., Ltd.

Startup Seeking Strategic Partners (We especially welcome pump equipment manufacturers, dry-mix material suppliers, etc.)

Join us to share the dividends of this new system method in the same track.We are looking for more than just capital; we seek long-term partners to create value together. If you are focused on construction technology innovation or possess relevant industry resources and investment plans, please contact us to obtain the business plan and further cooperation details.

Information

Traditional Methods Till Now

Traditional Methods Till Now

Traditional Methods Till Now

Subscribe to Our Latest Updates